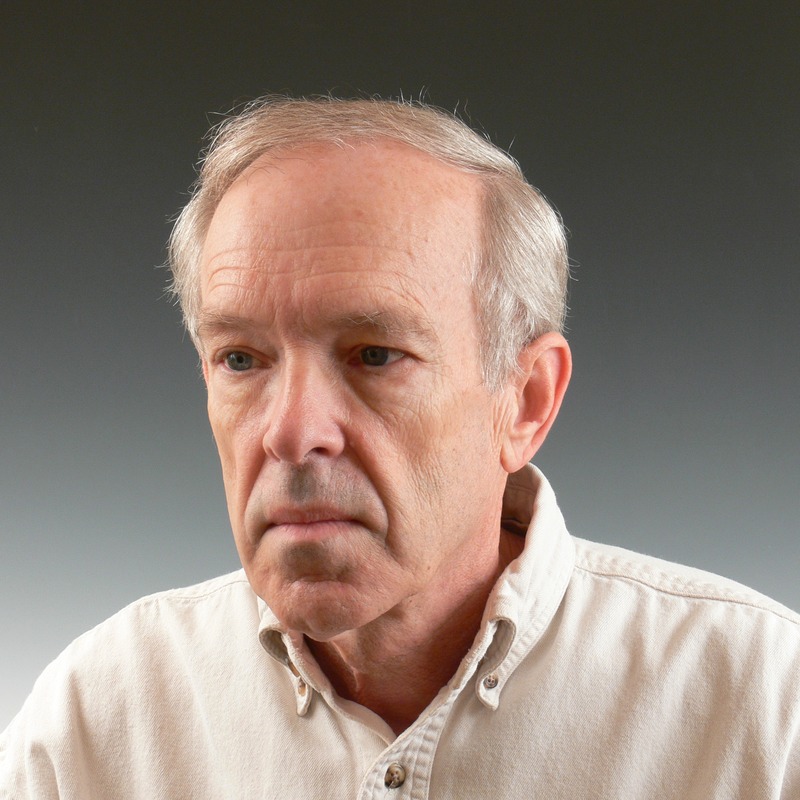

I am interested in the transformation and contrasts discovered through woodturning. The process of converting a featureless block of wood into a graceful, symmetrical form is always fascinating and full of surprises. I’ve been turning wood and exploring designs that combine turned features for over

twenty-five years.

My work in conventional hand turning and my engineering experience has recently led me to explore the fascinating field of ornamental turning. This old and specialized branch of turning has a unique history that parallels the development of the plain turning lathe. Advanced practitioners developed very complex machines to produce highly decorative work. The art form was popular with the aristocracy of Europe and interested George III of England, Louis XVI of France and Peter the Great of Russia.

The intricate devices made for the art include amazing mechanism with intriguing names like rose engines, geometric and eccentric chucks, swash plates, and goniostats. Machines that are the exemplars of the art were made by the Holtzapffel family in England during the 1800’s. Their machines represented the

state of the art in engineering and the five volume text published by Charles Holtzapffel is to this day the authority on the subject.

A few years ago, I happened to see a demonstration of a rose engine by the master turner Gorst Duplessis. After seeing a machine in action, it occurred to me that the motions accomplished by the complex arrangement of shafts, gears, cams, followers, and springs could be duplicated by simple motions produced by motor-driven shafts and lead screws that were more familiar to me as an electrical engineer.

I obtained parts surplussed or salvaged from industrial machines and constructed my simple machine so that with motion in three axes (one rotary and two linear) I could emulate the complex rocking and pumping motions of a rose engine. I use an old computer for control of the motors, the Linux operating system with real-time extensions, and an open-source software project for enhanced machine control (EMC).

I wrote my design software to emulate rose engine motions and was soon able to make the geometric patterns that are produced by moving the lathe shaft back and forth as it slowly rotates. After some initial success, I renewed my study of the history and patterns produced in the past and realized that I could also produce designs made with other equipment like eccentric chucks and cutting frames. I am now experimenting with new designs that are only possible with a post-industrial approach and the efficacy of computer control. I currently am experimenting with fractals and pseudo-random patterns.

Currently, I’m making small boxes following the traditions of the field. I turn the basic shapes for the body and the lid by hand on my old manual lathe and transfer the parts back and forth to my emulator machine for decoration. The work is quite

demanding in the precision required for the pattern work and in the extreme attention to detail needed for the many steps in the process. In addition to the unlimited possibilities for design, I’ve found new ways to make mistakes but each completed work adds to the learning process and my design repertoire.

Website

http://www.deweygarrett.com